Passed IS09001: 2000 quality management system and ISO/TSl6949: 2002 quality management system certification.

East Side of Dongxi Road, Linping Hangzhou, China.

86-571-86157772

86-571-86157772

In the automotive manufacturing industry, how do precision spindle ball bearings...

In the machine tool manufacturing industry, what kind of rotation speed and stab...

In the semiconductor manufacturing industry, how does the wear resistance of pre...

In the aerospace field, how do high-precision angular contact ball bearings meet...

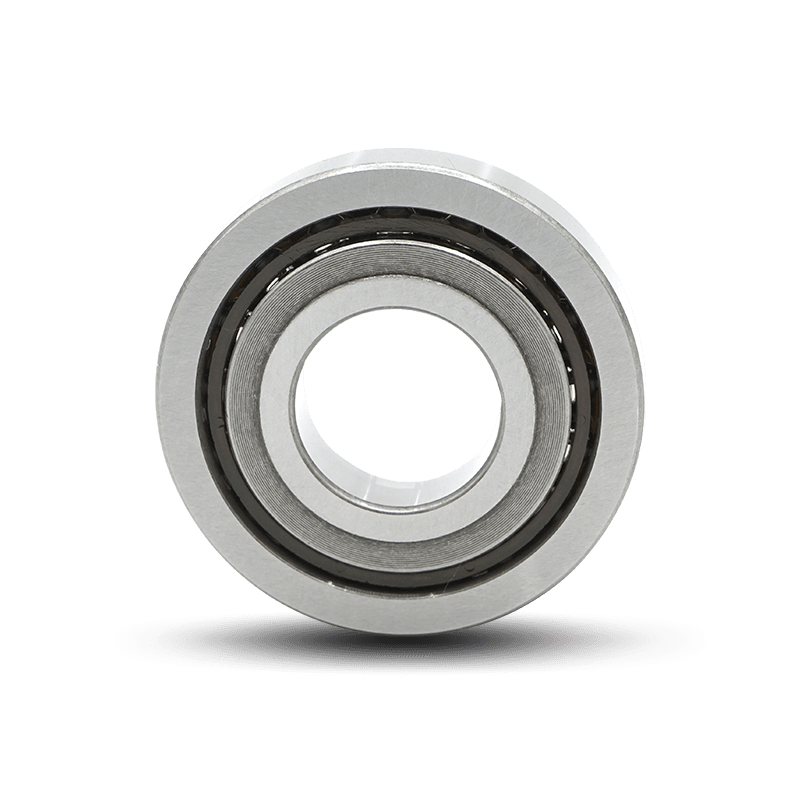

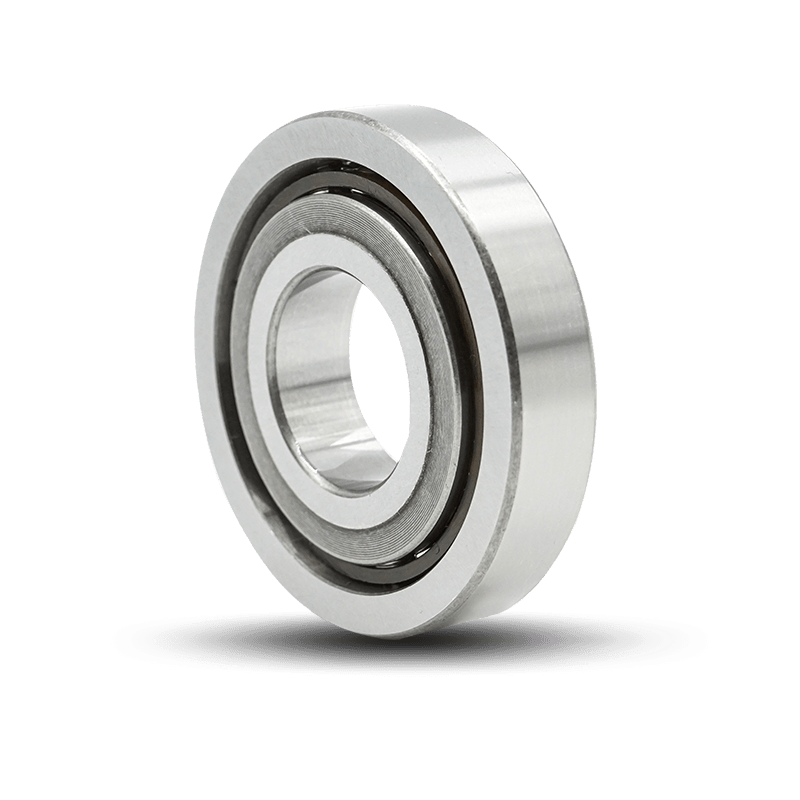

1. High precision: Angular Contact Ball Bearing have high precision and accuracy, which makes them ideal for use in applications that require high precision.

2. High Load Capacity: These bearings are designed to withstand high radial and axial loads, making them suitable for high speed applications.

3. Durability: The Angular Contact Ball Bearing is made of high-quality materials and designed to withstand heavy use and provide long-lasting performance.

4. Ease of Installation: These bearings are designed for ease of installation which makes them ideal for applications where quick and easy installation is required.

5. Low Friction: Angular Contact Ball Bearing are designed to have low friction, which makes them ideal for applications where low friction is important.

6. High Speed: These bearings are designed for high speed operation and are ideal for high speed applications.

7. Versatility: Angular Contact Ball Bearing is versatile and can be used in a wide range of applications, including machine tools, precision machinery, and automotive.

8. Cost-effective: Angular Contact Ball Bearing is cost-effective and value for money.

9. Maintenance Free: These bearings are designed to be maintenance free which makes them ideal for applications requiring low maintenance.

Angular Contact Ball Bearing plays a vital role in various industries and applications. They are designed to handle high axial and radial loads and provide high precision and stability. These bearings are typically used in applications where shafts are positioned at an angle to each other. One of the main advantages of Angular Contact Ball Bearing is their ability to withstand high radial and axial loads. This makes them ideal for use in high-precision devices.Another key feature of Angular Contact Ball Bearing is their ability to provide a high level of stability and precision. This is due to their design allowing the load to be evenly distributed over the bearing surface. This results in reduced friction and extended bearing life, making them ideal for use in demanding applications. Angular Contact Ball Bearing is also very durable and has a long lifespan. This is due to the use of high-quality materials, such as steel or ceramics, and advanced manufacturing processes. This makes them ideal for use in harsh environments where they are exposed to high temperatures, dust, and other contaminants.

1. Machine tool spindle: Angular Contact Ball Bearing is used for high speed machine tool spindle to provide high precision and high speed rotation performance.

2. Robotics: Since Angular Contact Ball Bearing can handle high loads and provide high precision, it is often used in robotic applications.

3. Aerospace: Angular Contact Ball Bearing are used in aerospace applications such as aircraft engines as they are able to handle high loads and provide high accuracy.

4. Wind turbines: Angular Contact Ball Bearing is used in wind turbines to support the rotor and provide high precision and high speed rotation performance.

5. Automotive: Angular Contact Ball Bearing are used in automotive applications such as drive shafts, wheel bearings, and drivetrains because of their ability to handle high loads and provide high precision.

6. Medical Equipment: Angular Contact Ball Bearing is used in medical equipment such as MRI machines and CT scanners as they are able to handle high loads and provide high accuracy.

7. Industrial Equipment: Angular Contact Ball Bearing is used in a range of industrial equipment such as pumps, compressors and conveyor systems because of their ability to handle high loads and provide high precision.

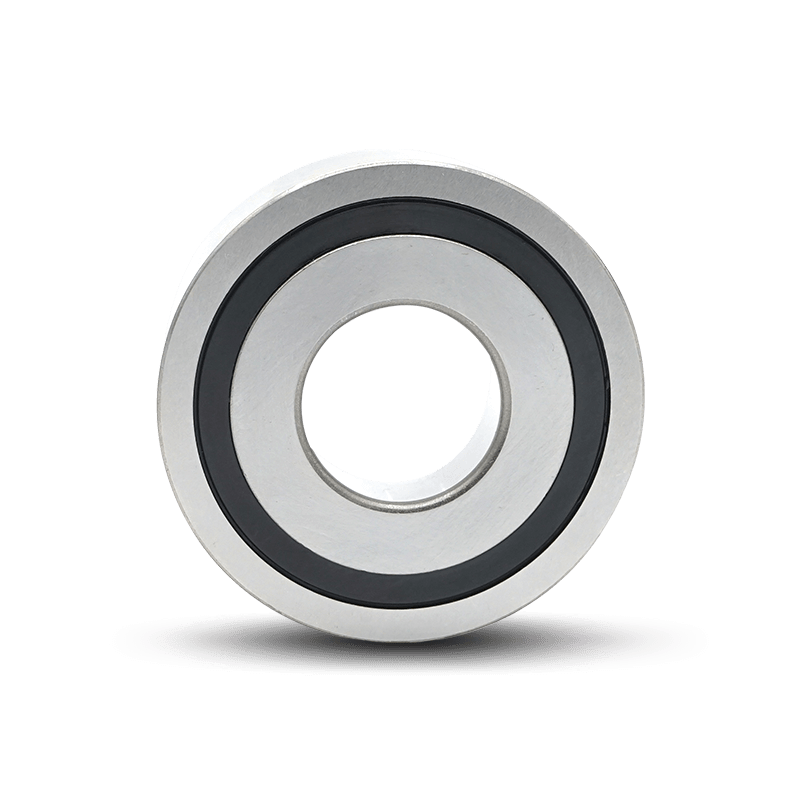

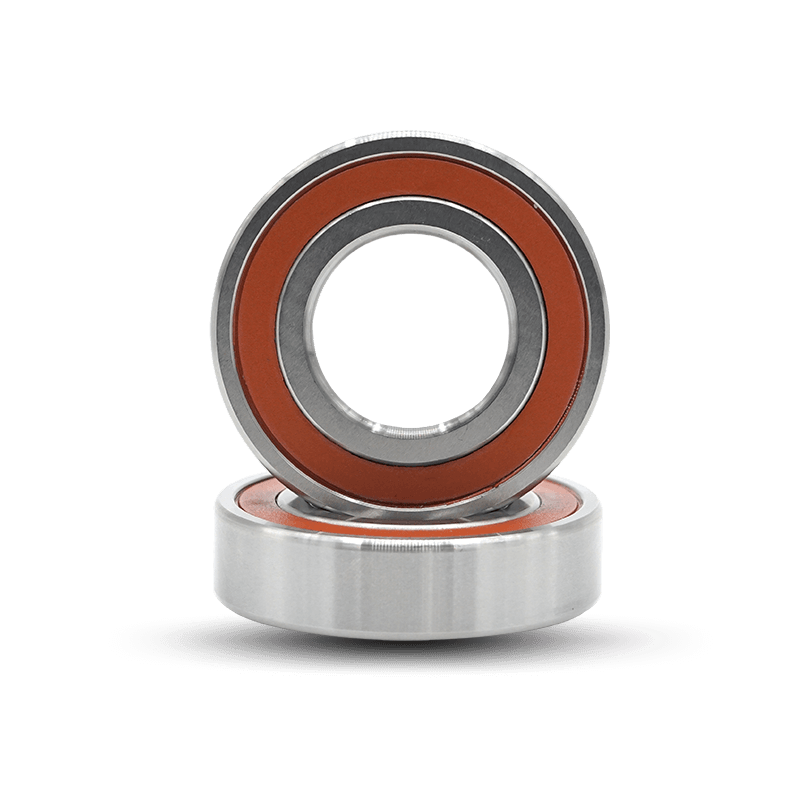

Angular Contact Ball Bearing is widely used in various industries for its high precision and reliability. These bearings can be customized to meet specific application requirements. Some customization options include:

1. Dimensions: Bearing dimensions can be customized according to application requirements.

2. Material: The material of the bearing can be customized to match the operating conditions and environment.

3. Configuration: The configuration of the bearing can be customized to meet the load and speed requirements of the application.

4. Preload: The preload of the bearing can be customized to meet the requirements of the application.

5. Clearance: The clearance of the bearing can be customized to meet the requirements of the application.

6. Seal type: The type of seal used on the bearing can be customized to meet the application requirements.

7. Lubrication: The type of lubrication used on the bearing can be customized according to the application requirements.

Customizing the Angular Contact Ball Bearing is important to ensure the best performance and service life of the bearing. It helps to match bearings to specific application requirements, reducing the risk of failure and ensuring smooth operation. Using advanced manufacturing techniques and engineering expertise, angular contact ball bearing can be customized to meet the specific needs of an application.