Passed IS09001: 2000 quality management system and ISO/TSl6949: 2002 quality management system certification.

Features:

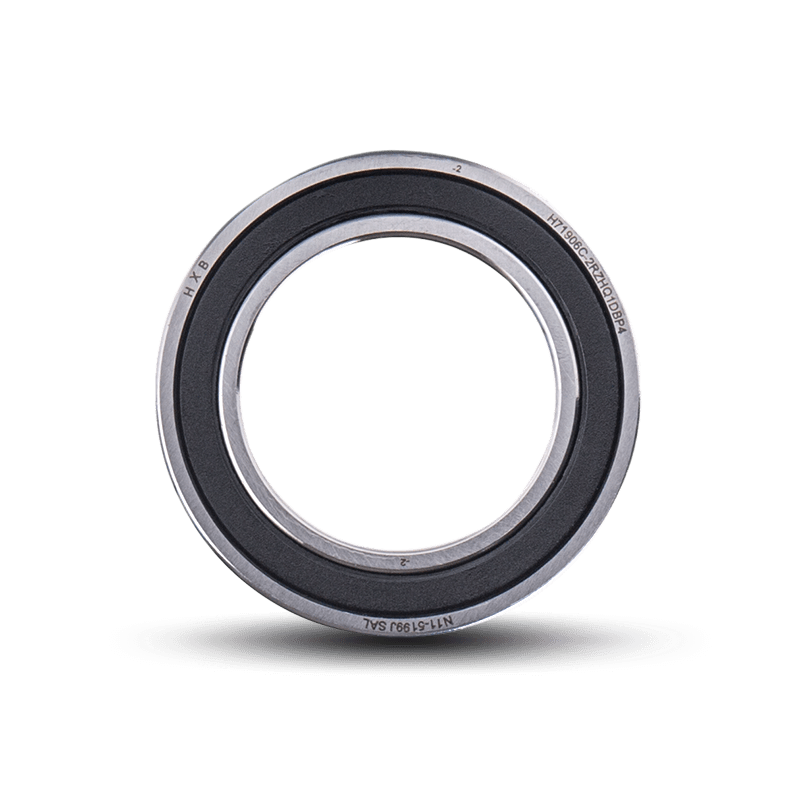

HXB thin section ball bearings improved machine tool performance and reduce energy loss, which widely used in precision machine tool spindle\high speed motor\robot\CNC router\ wood-working machine\gear box\ .

Series: 718××,719××

Contact angle: C(15°),AC(25°)

East Side of Dongxi Road, Linping Hangzhou, China.

86-571-86157772

86-571-86157772

In the automotive manufacturing industry, how do precision spindle ball bearings...

In the machine tool manufacturing industry, what kind of rotation speed and stab...

In the semiconductor manufacturing industry, how does the wear resistance of pre...

In the aerospace field, how do high-precision angular contact ball bearings meet...

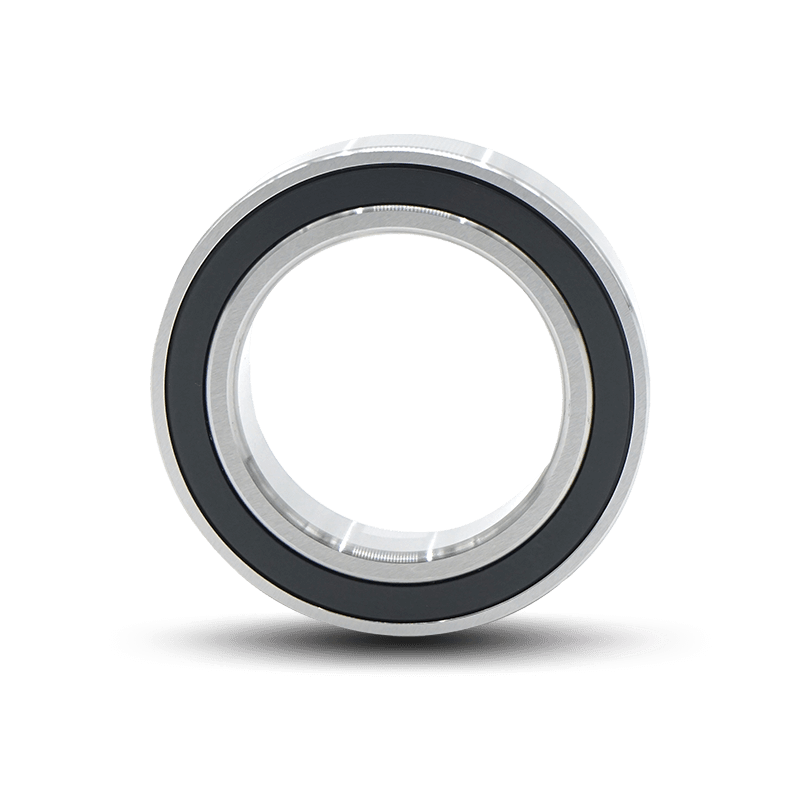

Thin Section Ball Bearing are rolling bearings used in applications where space is limited and weight needs to be kept to a minimum. Unlike traditional bearings that use cylindrical rollers or balls, Thin Section Ball Bearing use thin flat plates called raceways that are shaped like washers. This unique design enables the bearing to be installed in areas with limited space, while still providing the load carrying capacity of larger bearings.

Thin Section Ball Bearing operate like any other type of rolling bearing. The balls, or rollers, sit between the races and are spaced apart by retainers that keep them in place as they rotate. The race itself is housed in a housing usually made of metal or plastic.

As the bearing rotates, the balls or rollers move along the raceways, thereby transferring the load from one raceway to the other. This reduces friction between the raceways and rolling elements, which reduces drag and increases efficiency. The Thin Section Ball Bearing design also allows for precise alignment and control, making it ideal for applications requiring high precision and repeatability.

One of the key industries for Thin Section Ball Bearing is aerospace. In this industry, the use of Thin Section Ball Bearing helps reduce the overall weight of the aircraft, making it more fuel efficient and allowing it to operate at higher altitudes. The thin-section design also helps to minimize vibration and reduce noise levels, which are key factors for safe and comfortable flying.

Another industry that relies heavily on Thin Section Ball Bearing is the medical device industry. In this industry, these bearings are used in various medical equipment such as X-ray machines, CT scanners and MRI machines. They are ideal for use in medical equipment due to their high precision and stability, which is critical for generating accurate diagnostic images. Additionally, the Thin Section Ball Bearing is lightweight and compact, making it ideal for use in portable medical devices, enabling medical professionals to provide care in remote locations.

The industrial automation industry is another major user of Thin Section Ball Bearing. These bearings are used in various types of industrial equipment such as conveyor systems, robotics and automated production lines. Thin Section Ball Bearing offer high precision, low friction, and high reliability, making them ideal for high-speed production environments. They also offer a low-profile design that helps reduce the overall size of the device and increase efficiency.

Thin Section Ball Bearing is also widely used in the renewable energy industry. In this industry, they are used in various types of wind turbines and solar panels. Bearings are critical to ensuring that the rotors of wind turbines and the panels of solar panels move smoothly and efficiently, which is critical to producing clean energy.

The main benefits of Thin Section Ball Bearing include its compact size, high load carrying capacity and low friction. These bearings are also extremely durable and reliable, making them suitable for a wide range of applications including aerospace, industrial and medical equipment.

These bearings are designed to be as thin as possible to fit in tight spaces where other types of bearings cannot. This makes them ideal for use in applications such as motors, actuators and gearboxes where space is at a premium.

Another benefit of Thin Section Ball Bearing is their high load carrying capacity. These bearings are designed to carry heavy loads, making them suitable for applications requiring high precision and stability. Additionally, they are designed to operate with low friction, which contributes to the efficiency and accuracy of the equipment used.

Thin Section Ball Bearing is also very durable and reliable. They are made of high-quality materials designed to withstand extreme conditions and provide a long service life. This makes them ideal for use in applications where reliability and durability are critical, such as aerospace, industrial and medical equipment.

The first step in ensuring a proper fit is to accurately measure the housing and shaft dimensions where the bearing will be installed. This includes verifying bore diameter, outside diameter, width, and any tolerances or interference fits.

It is also important to consider the operating conditions the bearing will face, including load, speed, temperature and environmental factors such as humidity or contamination. This information helps determine the appropriate bearing material and lubrication requirements.

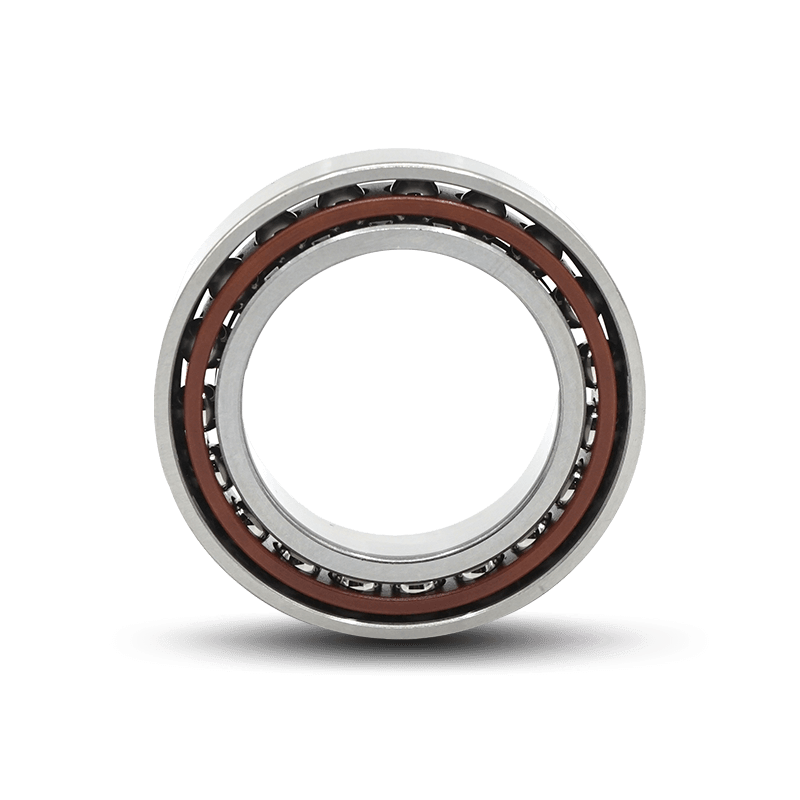

In addition, the choice of bearing configuration, such as radial or angular contact, open or sealed, and cage type, affects bearing performance and life. Selecting the correct configuration based on application requirements is critical for optimum performance.

Proper mounting of bearings is also important to ensure proper fit and function. This includes cleaning the shaft and housing, using the correct installation tool, and ensuring proper alignment. Proper preload, or the initial load applied to a bearing, also affects bearing performance and life.

Regular maintenance and inspection of bearings also helps ensure proper fit and function. This includes checking for any signs of wear or damage and monitoring the bearings for any changes in noise or vibration levels.