Passed IS09001: 2000 quality management system and ISO/TSl6949: 2002 quality management system certification.

Features:

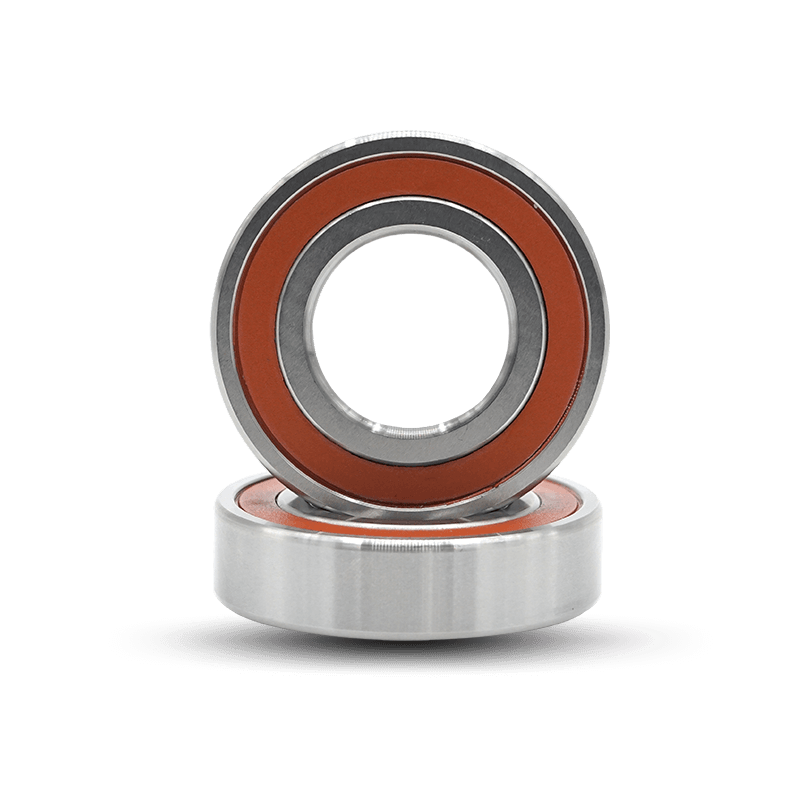

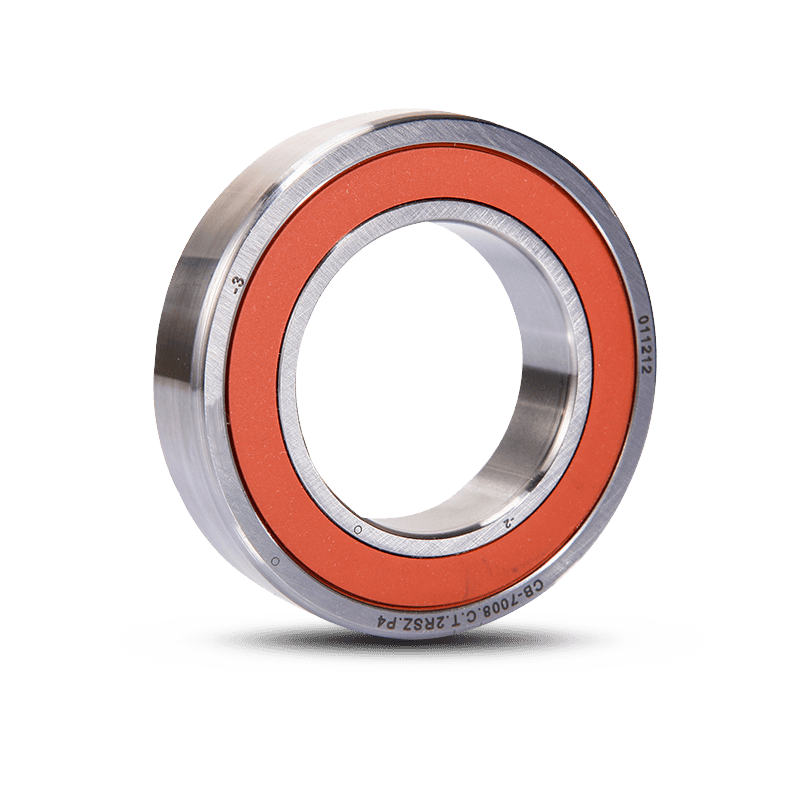

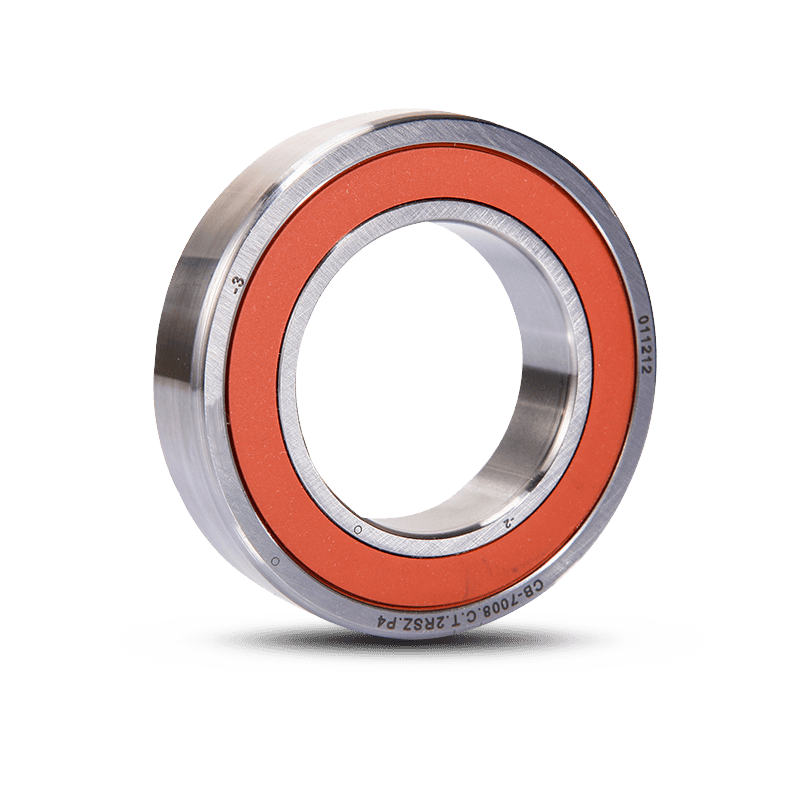

HXB sealed precision spindle bearings prepacked with grease for easier handing and mounting. It keeps working environment clean and safe. Also it provide customers with the ultimate maintenance free solution for bearings used in machine tool spindles.

For it’s good performance, HXB sealed precision spindle bearings widely used in precision machine tool spindle\high speed motor\robot\CNC router\ wood-working machine\gear box\

Series: 7×××,72××,73××

Contact angle: C(15°),AC(25°)

.jpg?imageView2/2/format/jp2)

East Side of Dongxi Road, Linping Hangzhou, China.

86-571-86157772

86-571-86157772

In the automotive manufacturing industry, how do precision spindle ball bearings...

In the machine tool manufacturing industry, what kind of rotation speed and stab...

In the semiconductor manufacturing industry, how does the wear resistance of pre...

In the aerospace field, how do high-precision angular contact ball bearings meet...

Precision Spindle Ball Bearing is a bearing designed to support high-precision rotary motion of machine tool spindles. It usually consists of an inner race, outer race, balls and a cage to hold the balls in place. The balls rotate between the inner and outer races, reducing friction and allowing smooth, high-speed spin. The precision of the bearings is achieved through tight tolerances in the manufacturing process and the use of high-quality materials. The high precision of these bearings increases the precision of the machining process, making them commonly used in applications such as grinding, turning and milling.

Precision Spindle Ball Bearing are essential components in many high precision mechanical applications. The main function of these bearings is to support the rotating spindle and reduce friction to ensure accurate and smooth rotational movement. They consist of an inner ring, an outer ring and balls held in place by a cage.

The inner ring is mounted on and rotates with the rotating shaft. The outer ring is usually fixed to the machine housing. The balls sit between the inner and outer rings and rotate freely, reducing friction between the two rings. The cage holds the balls in place and prevents them from bumping into each other.

In summary, Precision Spindle Ball Bearing are critical components in many high precision mechanical applications. By providing accurate and smooth rotary motion, they help ensure the precision and reliability of these machines. Combining precision, durability and reliability, these bearings are a key component of modern manufacturing techniques.

Precision Spindle Ball Bearing is a bearing used in high-speed applications such as machine tool spindles, high-speed electric motors and other high-speed rotating equipment. Precision Spindle Ball Bearing are available in various types designed to meet the specific needs of different applications.

One type of precision spindle ball bearing is the angular contact ball bearing, which is designed to accommodate high radial loads and high axial loads in one direction. This type of bearing is typically used in high speed spindle applications.

Another type of Precision Spindle Ball Bearing is the Radial Ball Bearing, which is designed to support radial loads. This type of bearing is typically used in low speed applications such as those found in electric motors and other types of machinery.

The third type of Precision Spindle Ball Bearing is a thrust ball bearing, which is designed to support axial loads in a single direction. This type of bearing is typically used in high-speed applications, such as those found in aircraft engines and other high-speed rotating equipment.

There are also combined radial and thrust ball bearings, designed to support radial and axial loads. This type of bearing is typically used in applications where both types of loads are present, such as machine tool spindles and other high-speed rotating equipment.

1. Load capacity is an important factor to consider when selecting precision spindle ball bearing. Load capacity will determine the strength and durability of the bearing and ensure it can withstand the demands of the application.

2. Accuracy requirements must be considered. Precision Spindle Ball Bearing are designed to provide precise and smooth rotational motion, so the level of precision required will affect the type of bearing selected.

3. When selecting a Precision Spindle Ball Bearing, operating conditions should be considered, including temperature, speed and vibration level. These conditions affect bearing performance and service life, so it is important to select bearings that can withstand specific operating conditions.

4. Bearing size and design should be considered to ensure proper fit in the machine. Bearings come in a variety of sizes and designs, and it is important to choose a bearing that matches the size and design of your machine.

5. The cost of bearings is also a factor to consider. High-precision bearings can be expensive, but investing in high-quality bearings can help reduce maintenance costs and improve the overall performance of your machine.

Precision Spindle Ball Bearing are critical components in many machinery and equipment applications. They are designed to provide smooth, high-speed rotary motion and support heavy loads. Proper maintenance and repair of these bearings is very important to ensure optimum performance and service life. We'll cover the basics of Precision Spindle Ball Bearing maintenance and repair, including common causes of failure, inspection techniques, and best practices for keeping these bearings in top condition. The most common cause of Precision Spindle Ball Bearing failure is improper lubrication. Regular lubrication is required to reduce friction, prevent wear and prevent corrosion. It is important to use the correct type of lubricant and follow the recommended reapplication intervals. Additionally, proper storage and handling of bearings helps prevent contamination that can cause damage. Inspection is a critical part of Precision Spindle Ball Bearing repair. Regular inspections can help spot potential problems before they become serious. To properly inspect bearings, it is important to remove them from the equipment and give them a thorough visual inspection, looking for signs of wear, corrosion or damage. Additionally, you may need specialized tools to measure the bearing's running accuracy and assess its overall condition. When servicing a Precision Spindle Ball Bearing, the first step is to determine the cause of the problem. If a bearing fails due to improper lubrication or contamination, it can usually be cleaned and re-lubricated. In other cases, such as damaged bearings or shafts, replacement may be required. When replacing bearings, always follow manufacturer's specifications and use only genuine parts.