Passed IS09001: 2000 quality management system and ISO/TSl6949: 2002 quality management system certification.

Features:

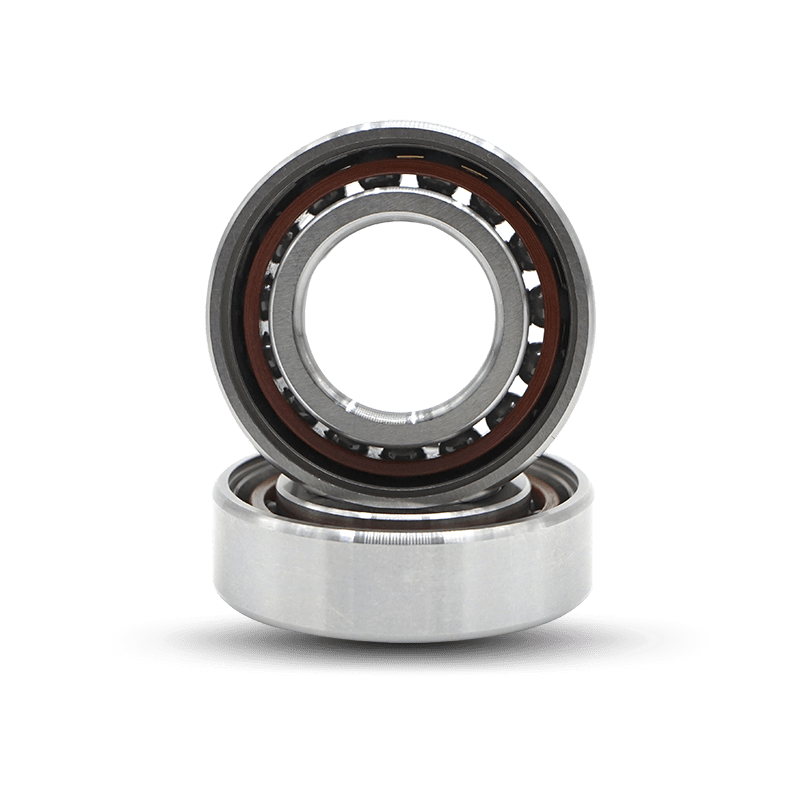

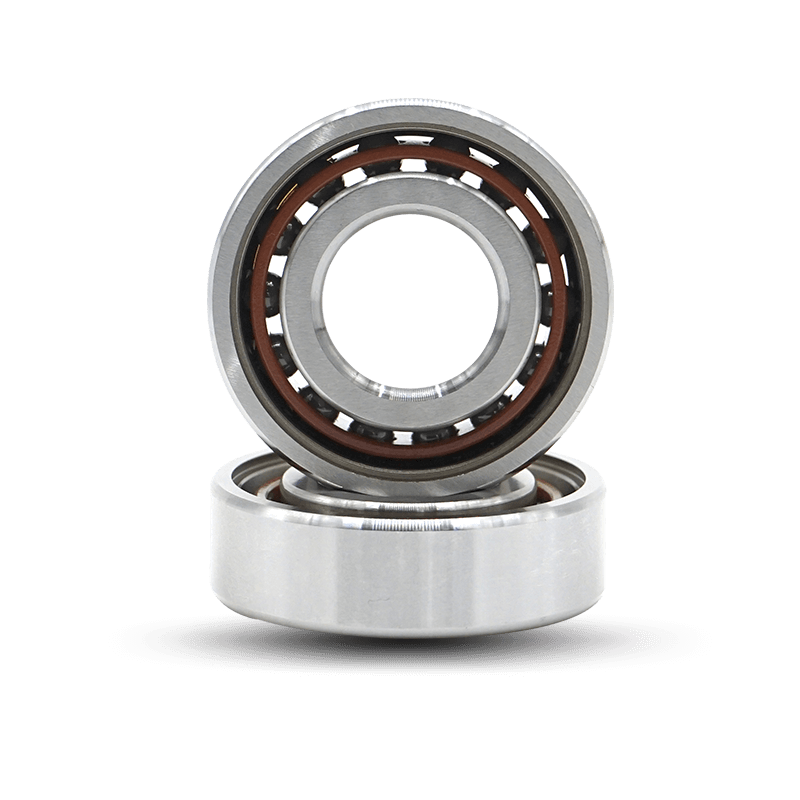

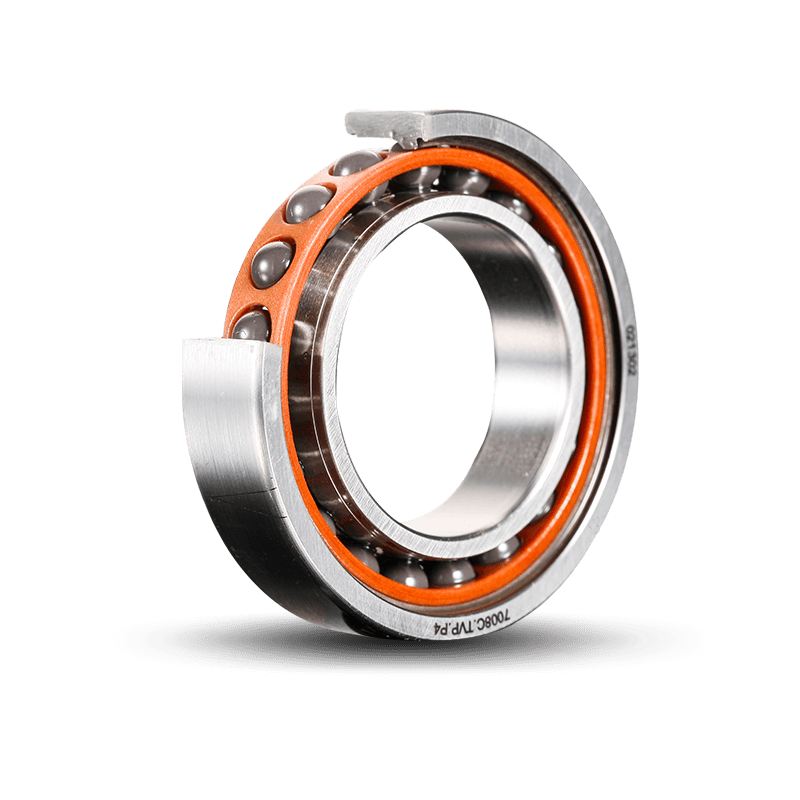

HXB angular contact ball bearings can accommodate axial loads in one direction . This type of bearing is typically adjusted against a second bearing. This kind of bearing improved machine tool performance and reduce energy loss, which widely used in precision machine tool spindle\high speed motor\robot\CNC router\ wood-working machine\gear box\

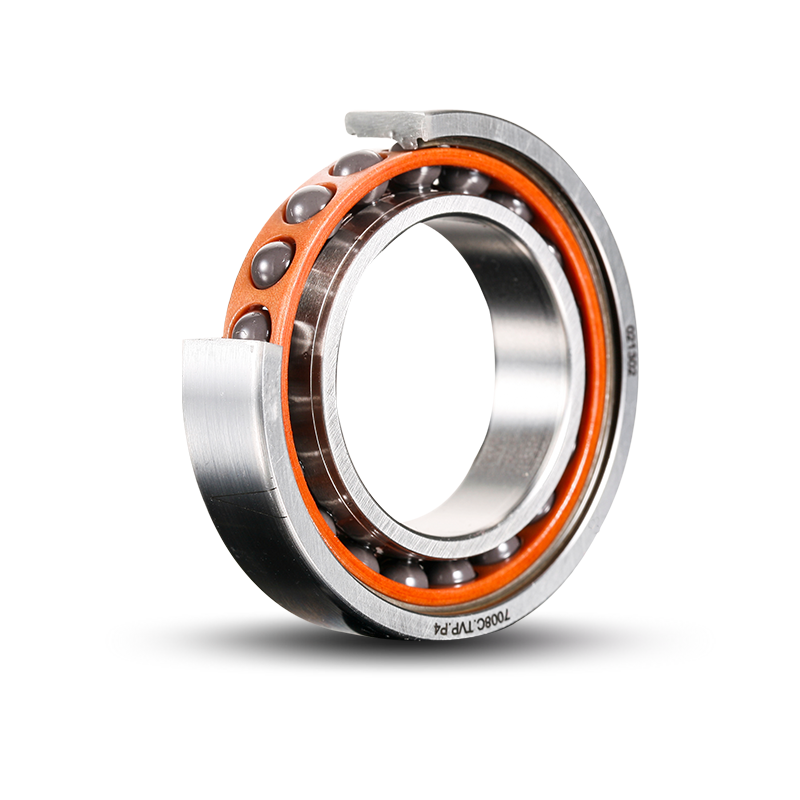

Series: 7×××,72××,73××

Contact angle: C(15°),AC(25°)

Arrangement: SU/DB/DF/DT/TBT/TFT/QBC.

East Side of Dongxi Road, Linping Hangzhou, China.

86-571-86157772

86-571-86157772

In the automotive manufacturing industry, how do precision spindle ball bearings...

In the machine tool manufacturing industry, what kind of rotation speed and stab...

In the semiconductor manufacturing industry, how does the wear resistance of pre...

In the aerospace field, how do high-precision angular contact ball bearings meet...

High precision angular contact ball bearings are widely used in various application fields due to their unique characteristics. These bearings are designed to accommodate axial loads in a single direction, making them ideal for high precision machinery such as electric motors, robotics, CNC milling machines, woodworking machines and gearboxes.

One of the main advantages of HXB High precision angular contact ball bearings is that they provide improved machine tool performance. Manufactured to precise tolerances, these bearings ensure high precision and stability in operation. This improves machine performance and reduces energy loss, helping to extend machine life and reduce maintenance costs.

Another key feature of these bearings is that they are usually adjusted for a second bearing. This arrangement improves performance and stability as it helps to distribute loads evenly and reduces the risk of bearing failure. Additionally, these bearings are designed for high-speed operation, making them ideal for high-speed applications such as CNC milling machines and woodworking machinery.

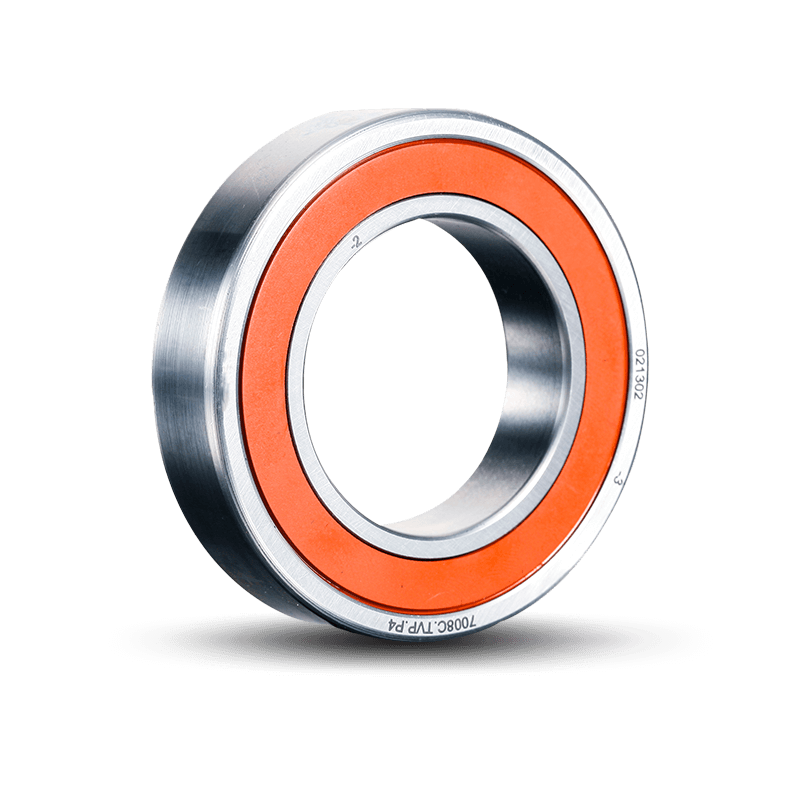

In addition to high precision and high performance, HXB High precision angular contact ball bearings are also extremely durable and long-lasting. These bearings are made from high quality materials ensuring they can withstand the demands of heavy use and high speed operation. This reduces downtime and maintenance costs, making it ideal for businesses looking to keep their machines running smoothly and efficiently.

In conclusion, HXB High precision angular contact ball bearings are ideal for businesses looking to improve mechanical performance and reduce energy loss. These bearings are designed to handle high precision and high speed operations and are manufactured to precise tolerances for stability and accuracy. Whether you want to improve the performance of motors, robots, CNC routers, woodworking machines or gearboxes, HXB High precision angular contact ball bearings are the perfect solution.

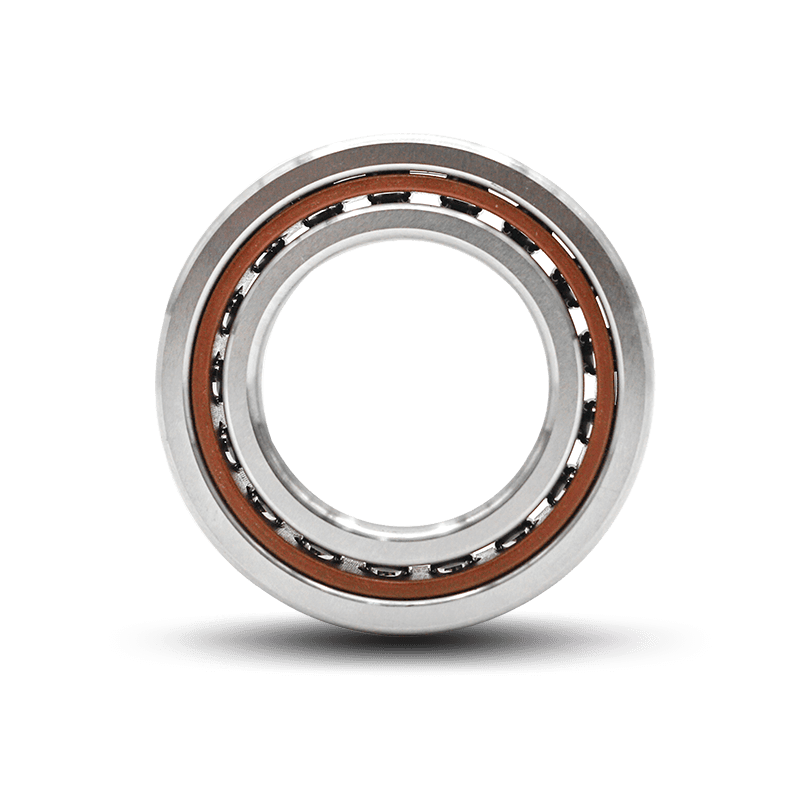

High precision angular contact ball bearings series 7xxx, 72xxx and 73xxx are designed for high precision and high speed applications. These bearings are suitable for machine tools, robots and other high performance machinery.

The 7xxx series is a single row design. High precision and rigidity make this series ideal for high-speed spindles and other precision applications.

Bearings in the 72xxx series are designed for higher load carrying capacity than the 7xxx series. This series adopts double-row design, which is more suitable for applications with high radial and axial loads.

Bearings in the 73xxx series are well suited for applications with high axial loads and moderate radial loads. These bearings are a double row design with a split inner ring and are ideal for applications where shaft deflection or misalignment is a concern.

All three series are available in various sizes and configurations for a variety of applications. Additionally, these bearings are designed for high durability and reliability, ensuring long-lasting performance in demanding environments.

In summary, the High precision angular contact ball bearings series 7xxx, 72xxx and 73xxx are ideal for a range of high precision and high speed applications. With their precision grade steel construction, high precision and high load capacity, these bearings are designed for optimum performance and long-lasting durability.

High precision angular contact ball bearings are key components in various industrial and engineering applications. They are designed to handle heavy loads and high rotational speeds, and are used in high-precision applications requiring the highest levels of precision and stability.

One of the most notable advantages of High precision angular contact ball bearings is their ability to handle high radial and axial loads simultaneously. This makes them ideal for applications with uneven load distribution, such as machines and equipment that require high rotational speeds.

Another advantage of these bearings is their high precision. They are designed to tight tolerances, ensuring that the bearings maintain precise positioning even under heavy loads. This makes them ideal for high precision applications such as aerospace, medical and metrology.

1. Aerospace: In the field of aerospace, High precision angular contact ball bearings are used in aircraft engines, turbines and gearboxes. Bearings help reduce friction and increase the reliability of these critical components.

2. Machine tools: High precision angular contact ball bearings are also used in machine tools such as CNC lathes and grinders. These bearings contribute to high precision and stability during cutting and grinding.

3. Medical equipment: High precision angular contact ball bearings are used in medical equipment such as X-ray machines, CT scanners and MRI machines. These bearings provide stability and accuracy of the rotating parts, ensuring high quality imaging.

4. High-speed machinery: High precision angular contact ball bearings are very suitable for high-speed machinery, such as centrifuges and high-speed pumps. These bearings help reduce friction, reduce noise and increase efficiency in these applications.